- Can achieve high - efficiency contour grinding and high - precision conical/vertical grinding by 5 - axis CNC control (simultaneous 4 - axis control)

- Can achieve grinding for spherical and uneven phases.

- Employs an automatic grinding wheel feed system for continuous high - precision grinding.

- Z axis can set a multiple stroke by the program. and can do the bottom grinding easily.

- Covers ceramics, glass,and other refractory materials.

- The sliding surface for each axis is made of quench - and - tempered lapped finish SKS3, which is excellent in durability.

- Machine dimensions 1,680 (W) x 2,205 (D) x 2,700 (H) mm, weight 3,150kg

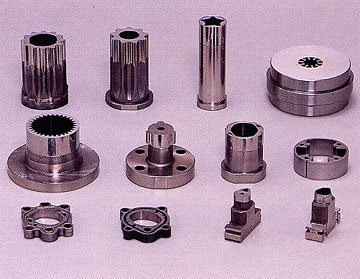

- Super - precision grinding of molds, cams, contoured parts, lenses, gauges, and other precision items.

| Positioning accuracy |

|

X, Y, and Z axis |

|

|

0.001mm

|

| Squarenesss |

|

X, Y, and Z axis |

|

|

0.002mm

|

| Parallelism |

|

|

|

|

0.002mm |

| Outline |

|

|

|

|

0.0025mm/ 100mm 100mm |

Item

|

Specifications

|

X axis stroke

|

450mm (horizontal)

|

Y axis stroke

|

250mm (transversal)

|

Z axis stroke

|

300mm (vertical)

|

U axis stroke

|

6mm (auto feed)

38mm(manual feed)

|

C axis stroke

|

360 deg

|

Table top surface - spindle head distance

|

100~400mm

|

Spindle center - column distance

|

243mm

|

Table work area size

|

620 x 300mm

|

Maximum table load capacity

|

100kg

|

T slot (width x lines x pitch)

|

12 x 3 x 80mm

|

| Rapid feed (G00) speed |

X, Y, Z axis |

|

C axis |

|

A axis |

|

1,000mm/min

40rpm

40rpm (option)

|

Grinding feed (G01, G02, G03) speed

|

150mm/min (Max)

|

| Manual feed (JOG) |

X, Y, Z axis |

|

C axis |

|

A axis |

|

450mm/min

30rpm

30rpm (option)

|

| Manual handle feed |

X, Y, Z axis |

|

C axis |

|

U axis |

|

0.01, 0.001, 0.0001mm

0.01, 0.001, 0.0001deg

0.01, 0.001, 0.0001mm

|

Grinding diameter

|

0.5mm to 50.0mm in dia. (when 10mm in dia.grinding wheel is used)

|

C axis continuous rotation speed

|

280rpm (Max)

|

High-frequency spindle rotation speed

(non - stage speed change)

|

30,000~60,000rpm

(standard)

6,000~24,000rpm

(option)

6,000~36,000rpm

(option)

60,000~80,000rpm

(option)

|

Power supply

|

3 200V 30A 50/60Hz 200V 30A 50/60Hz

|

Machine height

|

2,700mm

|

Floor space required

|

1,650 x 1,861mm

|

Weight

|

3,150kg

|

|

|

|

|

|