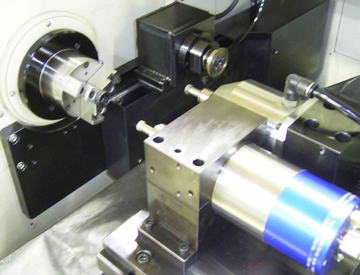

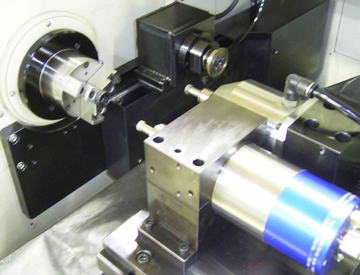

- Can achieve ultra-precision internal grinding by 2-axis CNC control (simultaneous 2-axis control) and external, conical, in-taper, edge and R phases.

- Employs double spindles specification for high-precision7high-efficiency composite grinding.

- Covers ceramics, glass and other refractory materials.

- It can be installed a system like an automatic loader and is available for fully automatic grinding on a medium to massive scale.

- The sliding surface for each axis is made of quenched, tempered and lapped SKS3 which is excellent in durability.

- Machine W2,150 x D2,500 x H1,925

- Weight 1,500kg

|

Positioning accuracy

|

X, Y axis

|

0.002mm

|

|

Roundness

|

0.0007mm/ 5mm 5mm

|

|

Table motion parallelism

|

X, Y axis

|

0.002mm

|

|

Table motion squareness

|

0.002mm

|

|

Repeat positioning accuracy

|

X, Y axis

|

0.002mm

|

|

Main axis rotation runout

|

0.002mm

|

Item

|

Specifications

|

X axis stroke

|

120mm (horizontal)

|

Y axis stroke

|

200mm (transversal)

|

Spindle head rpm

|

0~500rpm

|

FL - main axis center distance

|

1,100mm

|

|

|

450mm/min (JOG)

|

| Manual handle feed(1graduation) |

X, Y axis |

|

0.01, 0.001, 0.0001mm

|

Grinding dia. x length

|

25mm x 50mm 25mm x 50mm

|

Air Spindle

(special accessories)

|

FL-400 30,000~40,000rpm

FL-650 60,000~70,000rpm

FL-1200 110,000~120,000rpm

FL-1500 150,000~200,000rpm

|

High Frequency Spindle

(special accessories)

|

5,000~80,000rpm

|

Power requirements

|

3 200V 50A 50/60Hz 200V 50A 50/60Hz

|

Machine height

|

1,925mm

|

| Floor space required |

Machine |

|

2,150 x 2,500mm

|

| Weight |

Machine |

|

Coolant tank |

|

1,500kg

300kg (except coolant solution)

|

|

Operation Panel

|

|

|

*ACHIEVEMENT OF HIGH-PRECISION CIRCLE PROCESSING

*CAPABLE OF SPHERICAL7UNEVEN GRINDING

*REALIZATION OF TAKING SMALLER SPACE WITH ITS COMPACT DESIGN THAN BEFORE

Click Here

Double Spindles Specification (High Frequency Spindle

& Air Spindle)

|

Internal Grinding Diameter

|

5mm 5mm

|

|

Roundness

|

0.00043mm(0.43 ) )

|

|

Measuring Equipment

|

TR-262 (Taylor Hobson Ltd)

|

|